Product alias:

Tube End Closing Machine, Pipe End Closing Machine, tube forming closing machine, closing machine, tube sealing machine, sealing machine, tube end forming machine, spinning machine, tube spinning machine, tube closing machine, hydraulic metal pipe sealing machine , pipe end forming machine, metal pipe sealing machine, roll closing machine, roll forming machine, metal processing machine, gas spring cylinder end closing machine, gas spring cylinder slotting machine, gas spring cylinder edge folding machine, gas spring cylinder grooving machine, gas spring sealing machine, gas spring closing machine, roll close machine, gas spring machine, end rolling machine, end closing machine, cold sealing machine, tube rolling machine, gas lift , gas damper, suspa,stabilus

Scope of application :

Tube or pipe assembly products can be a complete or not complete tube end sealing .Its used in the industrial of gas spring, shock absorbers, Heat exchange, baby stroller, kids tricycle, baby playpen, bicycle, motorbike, automobile, exercise equipment,buffer, gas lift, deck chair, chaise lounge, furniture, suit hanger, lighting fixtures, house wares, sanitary wares, recreational facilities, rehabilitation and medical instruments, stainless chopsticks,…etc.

Feature of product:

It is used for the purpose of making tube ends in a wide range of sizes.

This product has a sturdy and durable construction. The materials used in the manufacturing of this product are of optimum quality.

We being one of the market leaders, consider providing optimum quality to be our priority. And thus, we process this product through a number of quality tests.

※Complete or not complete tube end sealing is alternative according to client's requirements .

※Adaptable to metal tube of various materials including iron, aluminum, copper, stainless steel, etc.

※Three process tooling will be running simultaneity , efficient productive and noise free .

※Simple operation with quick and safe manual control , a professional operator will not be required .

※Rapid mold shift device makes replacement of mold and point adjustment easier and quicker.

※Finished tube end has safe quality and nice exterior, and is secure from plastic cover falling off or skin scraped.

※Break through the traditional methods, integrated without heating, the sealed tube application will be plastic cover free and no need of tube end welding.

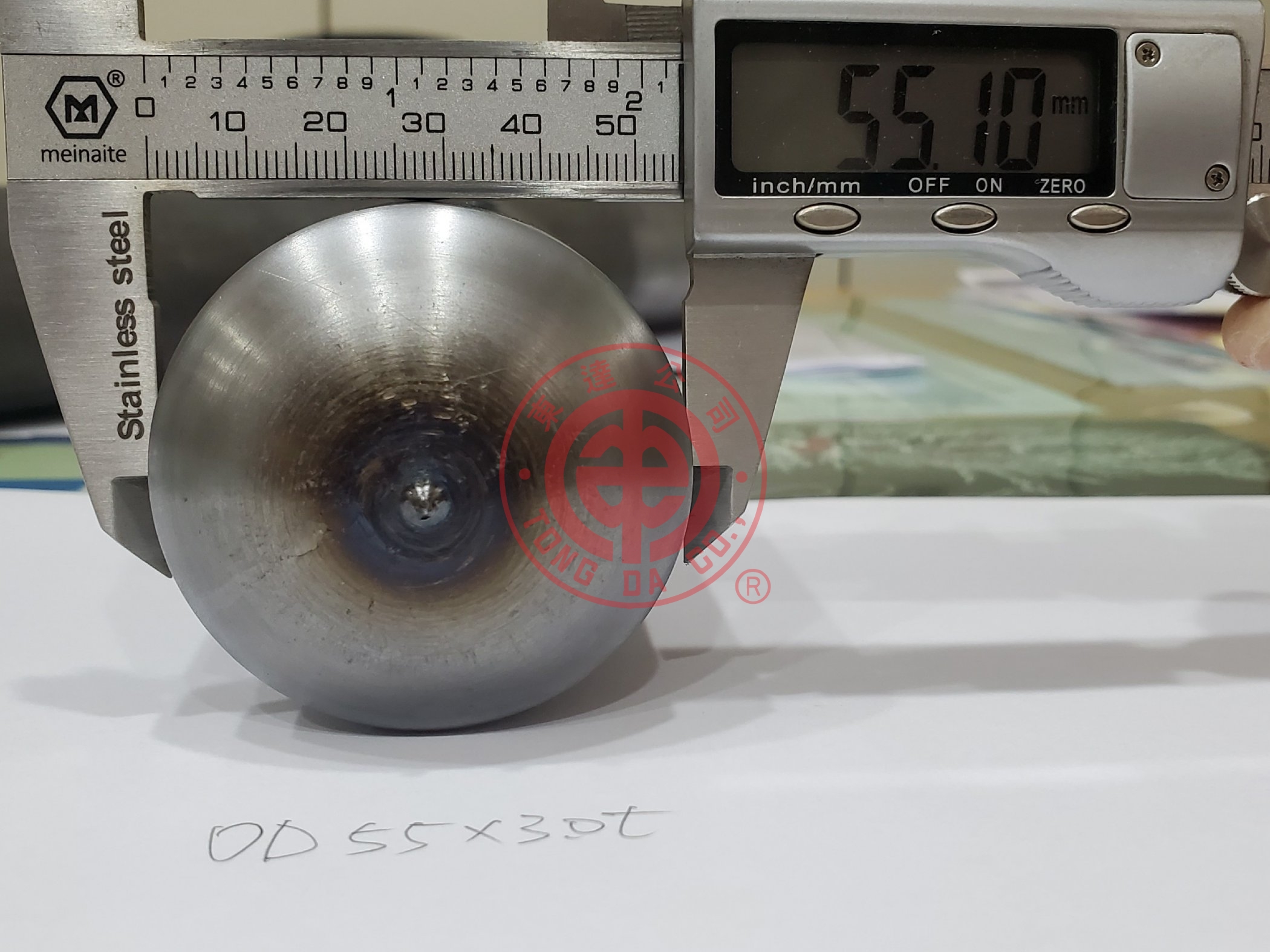

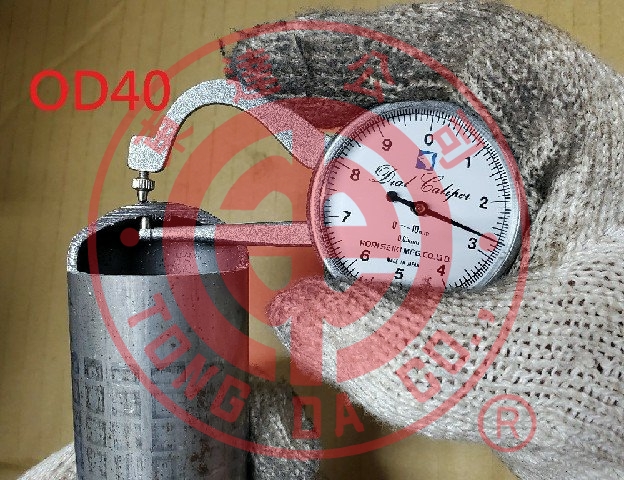

※Can easily adjust the arc degree and pore size.(have hole or no hole.)

※Finished tube end has safe quality and nice exterior, and is secure from plastic cover falling off or skin scraped.

※Easily-operated, even by an unprofessional person.

※The sealed tube application will be plastic cover free and no need of tube end welding.

※Rapid mold shift device makes replacement of mold and point adjustment easier and quicker.

for gas spring sealing machine, cold sealing, cold forming,cold closing ,tube closing,tube forming,tube forming

100% MADE IN TAIWAN

TD-31040 Tube sealing machine for gas spring,heat exchanger,chair,furniture,airbag machine

TD-31040 Tube end closing machine for gas spring,heat exchanger,chair,furniture,airbag machine

TD-31040 Tube forming machine for gas spring,heat exchanger,chair,furniture,airbag machine,Torsion Spring machine

*Sealing machine to process tube hardness have to less HRB55 and need enough ductility.

*Because it is a cold forming process, the tolerance will be unstable due to the factors of the pipe, and the tolerance of the incoming material will affect the overall tolerance. The tolerance of the incoming material must be as small as possible.

*Sealing machine to process tube weld bead have to firm, when sealed weld bead will not dehiscence.

*Outside dia less than 20mm, within length 1000mm can to install tube holder keep tube don't shake (need extra purchase).

*Stainless steel tube hardness is softer the better and good ductility, tube material weld bead have to firm.

*Tube outside dia and thickness have to collocation each other. Especially outside dia more than 25mm tube.

| 管徑大小 OD sizeψ(mm) | 3041B.3043B | |

| 最小管厚(mm) Min OD | 最大管厚(mm) Max OD | |

10~15 | 0.8 | 2.0 |

15~20 | 0.9 | 2.0 |

20~25 | 1.0 | 2.0 |

25~32 | 1.2 | 2.0 |

32~38 | 1.5 | 2.0 |

38~40 | 1.7 | 2.0 |

| Three Station-Tube Sealing Machine | Specification |

|---|---|

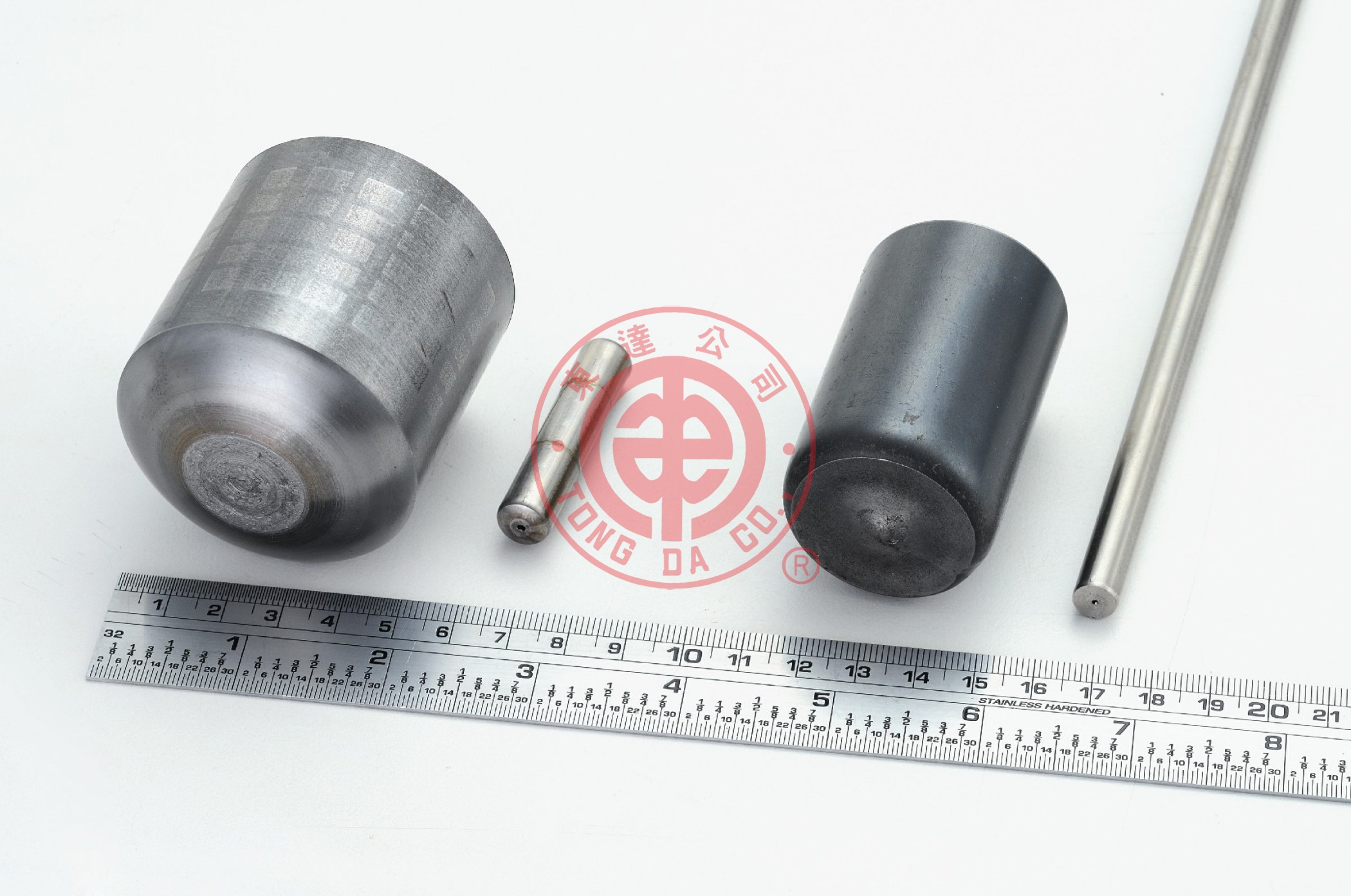

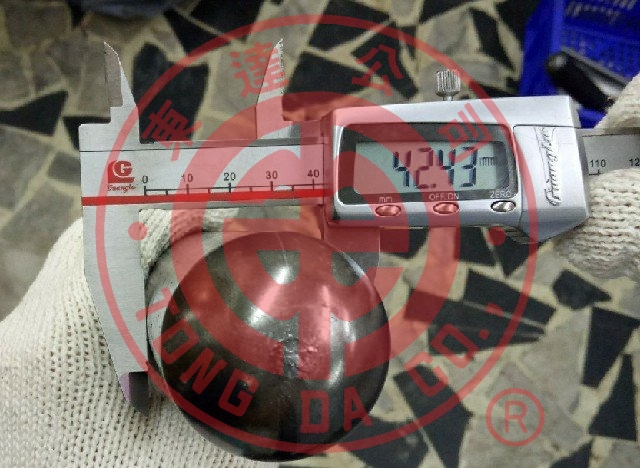

| Outer diameter of tube | 10 ~ 40mm |

| Thickness of tube | 0.8mm~2.0mm Tube diam. and thickness must match well. |

| Length of tube | unlimited |

| Speed of sealing tube | 8 seconds min., according to tube diam. and thickness |

| Horsepower | 11 HP |

| Total length | 2285 mm |

| Total width | 825 mm |

| Total height | 1185 mm |

| Net weight | 910 kgs |

| Gross weight | 1030 kgs |

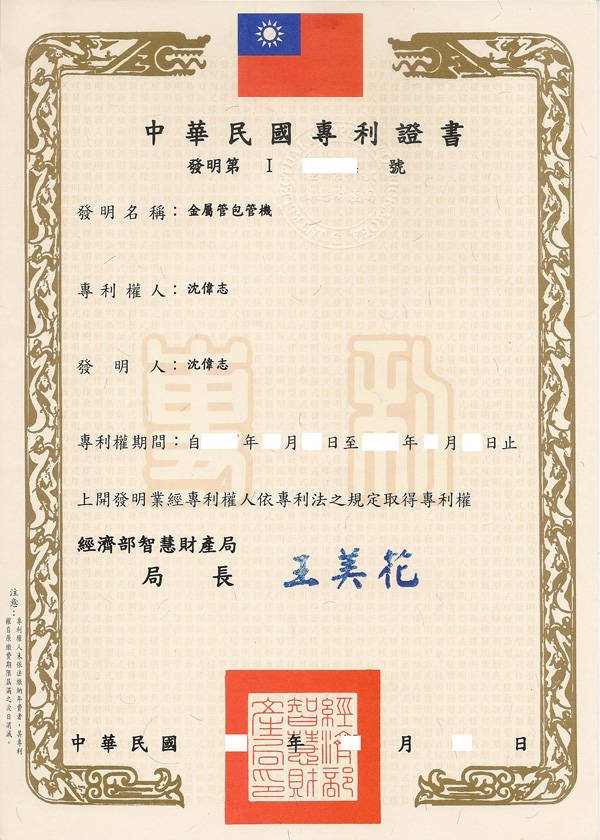

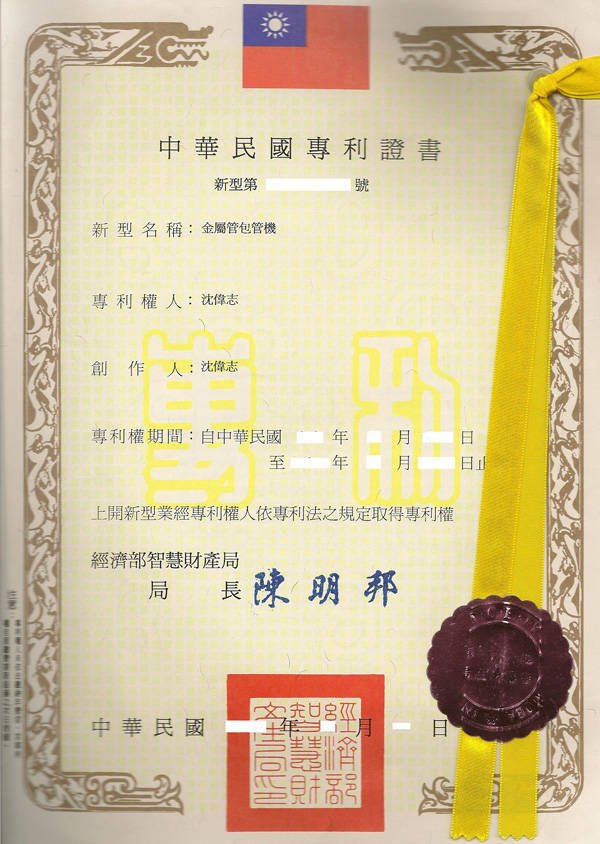

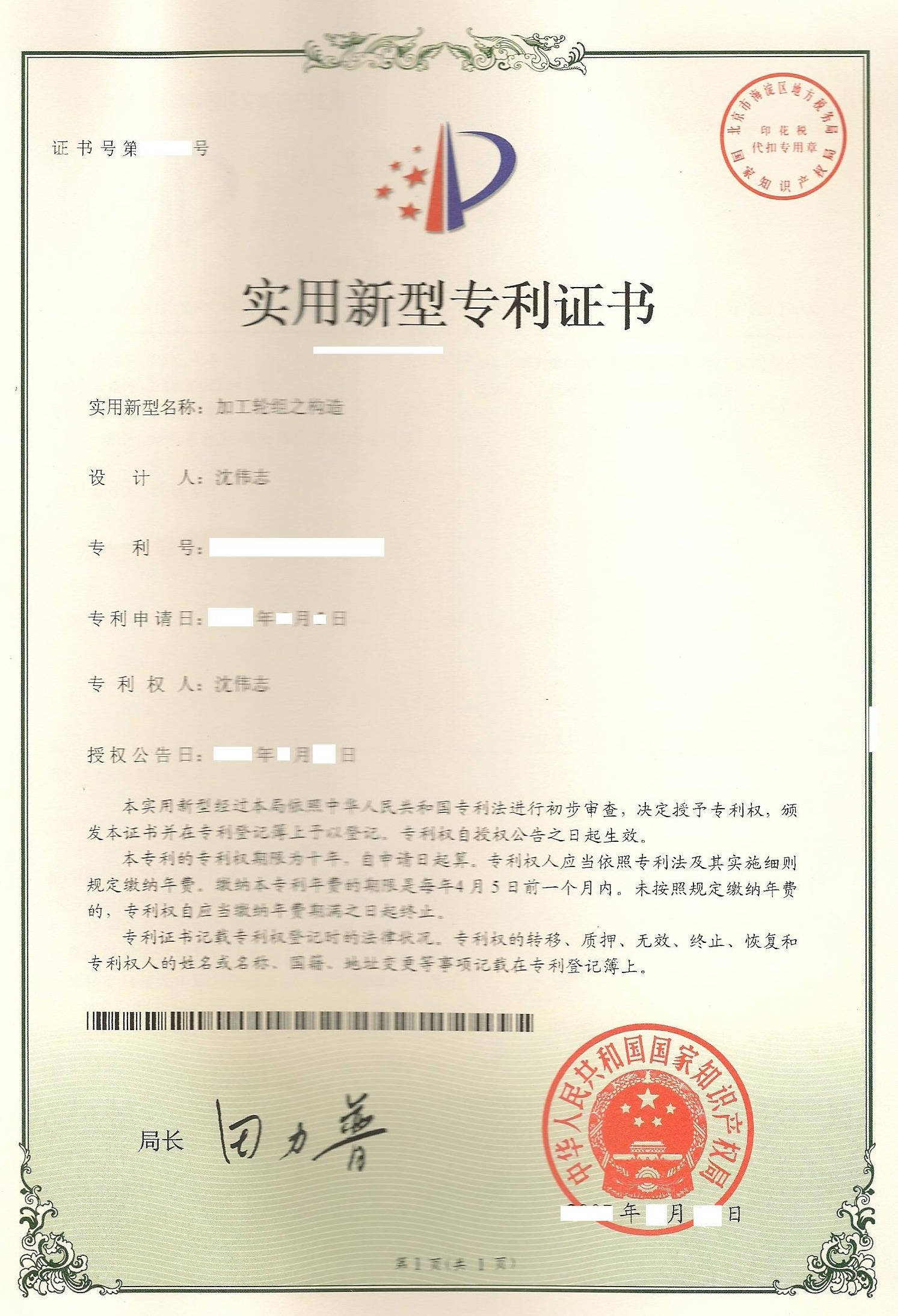

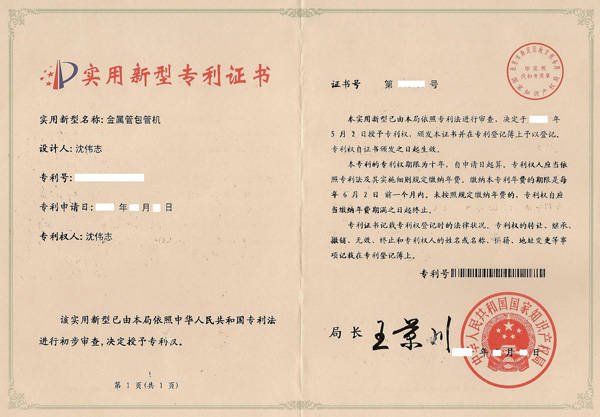

Patent Information:

Safety certification:

CE MARK

Partner company:

Sold to Germany gas spring factory , European, USA company, China, Thailand, Japanese car companies